Author: Miranda

Location: Miami, FL

Glow plugs, exhaust elbows, high pressure fuel pumps, injectors, feed pump, throttle cables… all of this has somehow worked it’s way into our daily vocabulary and into my working understanding of how a diesel engine performs. Now, you don’t grow up the daughter of a diesel mechanic and never hear this kind of talk, so I had a faint understanding of what some of these things were before we bought our sailboat. But, faint is the key word ladies and gentlemen.

Now all that has changed. Somewhat. I’m probably not ready for a second career in diesel engine repair, although I probably should be, as that’s where I’ll find myself (working at Dad’s family business) if this all goes to shit. But, I understand a HELL of a lot more than I did a month ago about the inner workings of our marine diesel engines. It’s had its frustrating moments, but it’s been fun to learn a whole different set of skills. Dad, I now have a much deeper understanding for why wrenches just need to go whizzing, airborne across the shop from time to time. That must feel so good. Since wrenches clearly have a higher density than water, I’ve yet to try it out.

So, what exactly have we been working on? Basically, we’ve had two major fixes on the engine and plethora of random upgrades/repairs around the boat in general.

Fun in the engine, version 1.0, occurred when we were pulling away from the dock at Dinner Key Marina, right after filling up our water tanks and cleaning the topsides of the boat. Just when we got about 6-8 feet from the dock, Pete looked at me with fear in his eyes and said, “I just lost the starboard engine. Pull us back on!” We were well past this point, and I told him I couldn’t reach it. The starboard engine was still running, but it had no power to throttle up. Assuming we could still head back to our mooring ball with one engine, I told him to turn the rudder hard to port and see if we could still go straight. He said, “Nope! It won’t do it. We gotta get back to the dock.”

Oh shit. Amongst all the other plotting my brain was doing to think of ways to get us back to the dock, somehow I had free neurons up there in the ole noggin to scan all the expensive boats around us, and estimate just how much they were all worth, and just how horrible it would be to careen into one. Oh goody. Luckily the wind was almost non-existent, and what little wind we had was pushing us back to the dock. Pete zigzagged us closer and closer to the dock, only going forward and backward a few feet at a time. We nosed into the dock bow-first, at about 45 degrees to the dock, and Pete leapt onto the pontoon with a stern line, and gradually pulled the butt-end of the boat flush with the dock.

Moral of the story- always check to make sure your engines will engage and throttle up BEFORE leaving the dock.

Once we got tied up again, Pete jumped down in the engine compartment, and I worked the throttle at the helm. The engine would idle just fine and go into gear just fine, but it wouldn’t actually throttle up and spin the propeller. We ripped apart the throttle box, but didn’t see anything interesting right away. Nothing different in the cables around the engine either.

After plenty of experimenting, we realized the throttle cable wasn’t actually pushing the engine to rev up, in either forward or reverse, but it did have some push at very low speed. If went very slowly, we could get back out to our mooring ball, and really dig into the problem. Our budget doesn’t really allow for nights spent on a T-dock for $4 per foot, per night (at 38 feet, you do the math), so we knew we’d feel better back on our mooring ball. We pushed off from the dock again, this time knowing that at very low speeds we could still get some steerage from our starboard engine.

We made it out to the mooring field and tied up just fine. Whew! After some substantial digging into our throttle box, we found a snapped throttle control cable. That it’ll do it.

Luckily, Pete was heading to Austral International the following day to pick up spare filters and impellers, and, luckily, they kept these throttle cables in stock. We picked up two and replaced both the port and starboard cables with new, and kept the old, still working, port cable for a spare.

Fun in the engine, version 2.0, has been an ongoing problem, and after weeks of troubleshooting, I think we have found the culprit. Basically, our port engine was taking a very long time to start. It always starts eventually, but we are cranking the poor girl for like 30-40 seconds to get her to go. Sometimes 50-60 seconds. That’s a long time. And, it’s gotten worse during the month that we’ve owned the boat. We certainly need our engines to be in tip-top condition before heading overseas, so we’ve been working our tails off to get this issue fixed. Basically, Pops told us that it could be one of two things: either the engine isn’t getting enough fuel or it’s not getting enough pressure, and cross your fingers that it’s a fuel issue because compression issues are one scary and expensive thing to fix.

So, logically, we started with the fuel injection system. We found a receipt that said Kenan (the last owner) had all the injectors rebuilt a week before we bought the boat, so we crossed that off the lift. Pete pried off the fuel injector pump, and I took it to bumblef%$# Miami to get it serviced. Some of the o-rings were bad, and it certainly looks prettier now, so we hoped this would fix it. After putting the bugger back on the engine, we found no change in the cranking time. So, we pulled off the feed pump, disassembled it, cleaned it up, and put it back on. Still no change.

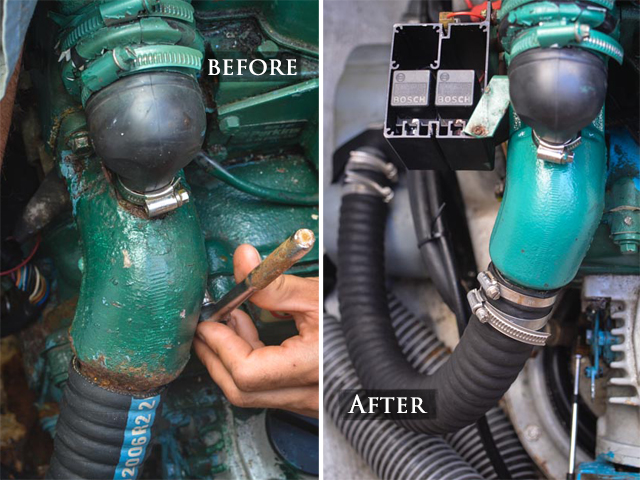

In the meantime, we also picked up two new exhaust elbows and replaced them on both engines. These guys help take the engine exhaust from the engine and mix it with sea water to cool it slightly so it can, then, go through a plastic muffler and out the exhaust hole on the side of the boat. This was one hell of a job as the nuts and bolts holding the elbows on the engine were a horrible, corroded mess. Pete spend many days hammering on the connections, soaking them in brake fluid, and expending lots of elbow grease to get the old elbows off. But, take a look at these before and after pictures. I think you’ll agree that it was worth it.

Look at the inside of that thing!! Gross!

So, given the amount of disgusting gunk that was almost completely plugging up our port-side exhaust elbow, we started to worry that the engine had been running way too hot (due to the lack of proper movement of coolant and exhaust), and maybe there was a crack in one of our pistons. Dear lord. This would be a massive job. MASSIVE. It requires lifting out the engine from the boat, removing a part that is both buried WAY inside the engine and VERY expensive to replace. Sweet Jesus, this could wreck our cruising budget.

After more troubleshooting with the great and powerful mechanic behind Pashouwer Farm Repair, he suggested looking at the glow plugs. And crossing those fingers even harder. This would a very cheap and easy fix, and it would show all the same symptoms that we were seeing in our port engine (whom Pete has semi-affectionately named Wendy). We pulled out all the glow plugs from both engines, tested them by running voltage through each one, and it looked as though four of the six were dead, going 0 for 3 on the port side. Or, we were sucky glow plug testers.

Glow plugs are used to warm up the cylinders before cranking your engine. They help start the engine faster by making the temperature high enough to catalyze ignition of the fuel. They are not spark plugs, and don’t confuse them as such. This is mechanic sacrilege, akin to calling the Super Bowl and the World Series, “you know, basically the same thing.” Hmmm… I guess Pete wouldn’t get that reference, but we won’t tell him I mentioned that, will we? 😉

Since they were cheap, we bought six- three new glow plugs to replace the dead ones on the port engine, one for the starboard side, and two more as spares for the starboard engine (Pete calls this little lady Belinda).

There are few things that bring the same level of relief as fixing a mechanical issue that’s taken weeks of troubleshooting, many hours of grunt work, and plenty of attempts that we thought would surely be the problem. Lordly, it feels amazing! Glow plugs. I adore your ease of removal and low price tag. It’s an odd item to go out on an engine, but I’m still over the moon that this was our issue. Also, it was really fun to troubleshot and “talk shop” with my father- getting to see him in his element reinforced the great respect I have for the guy. As soon as we popped the new ones in, our port engine started up like a champ. The progressively colder weather here Florida also explains why the issue was getting worse.

To go from cranking our engine for up to a minute, to getting it to start up immediately is a glorious, glorious feeling! Ahhhhh!

Some other fun times we’ve had aboard Tayrona lately include:

The installation of our brand new SSB radio. Thanks Gerry and Leo at Nautor Marine! These guys were amazing, and we’ll recommend wholeheartedly. Great guys, who did a bang-up job.

We installed bus bars for the wiring to and from the batteries and put our batteries into battery boxes. We are continually working on cleaning up the wiring around the boat. Doesn’t this…

…look so much nicer than this?

After much debate and looking into each and every alternative, we bought a new chartplotter and radar combo. The chartplotter that came with the boat worked just fine, but the radar unit wasn’t functioning at all. We spent a good deal of time troubleshooting it, but couldn’t figure it out. Also, we were having a very hard time finding the SD cards that are placed in the chartplotter to show the maps of where we’ll be cruising. The chips aren’t made anymore, so we had no promise that we’d find them for all the placed we’d like to visit. Both the plotter and radar units were on the older side, so we decided it was time for an upgrade. We installed both ourselves, which wasn’t hard, but it was time consuming.

We’ve changed oil, oil filters, and fuel filters on both our engines, as well as cleaned out the raw water strainers and replaced any bad impellers.

We marked the anchor chain in 5-meter increments. How this wasn’t already done on a 14-year-old boat astounds me. (2 zip ties = 20 meters of chain)

We’ve been spending so much money that we are also working hard to sell some things on the boat for a little extra cash flow in the other direction. We sold an extra dinghy, a second outboard motor, the old fridge compressor, the old SSB and tuner, the old chartplotter, but we are still will working on selling our Aquair Wind and Towing Generator. Any takers? 😉

Pete rewired the windless, as the wiring was a short circuit waiting to happen. Bare wires next to wet anchor chain… not a good plan.

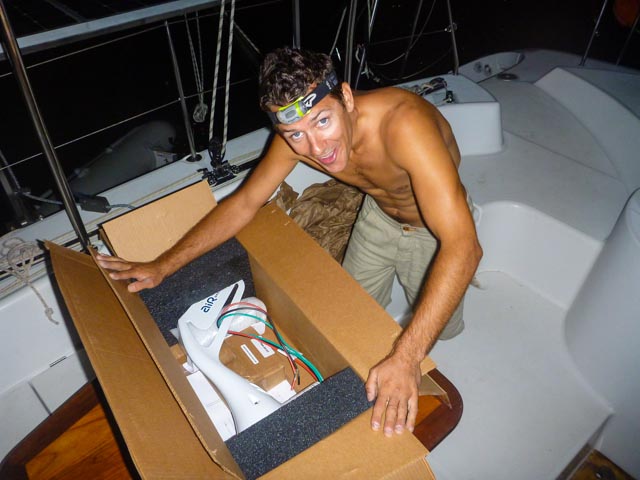

We also bit the bullet and bought a new wind generator! Like I said in an earlier post, we are really working hard to be energy neutral. One of the reasons that our port engine is in much worse shape than the starboard is due to the fact that it was being run once a day to charge our batteries. If we can make all the energy we need on a daily basis, using solar and wind, then we don’t need to run the engines just to charge our batteries.

And, low and behold, we also found the time to actually go sailing for an afternoon! We moved from a mooring ball at Dinner Key Marina to an anchorage in Marine Stadium. From here, the views of downtown Miami are stunning- especially at night. And the rent is cheap too. We like free.

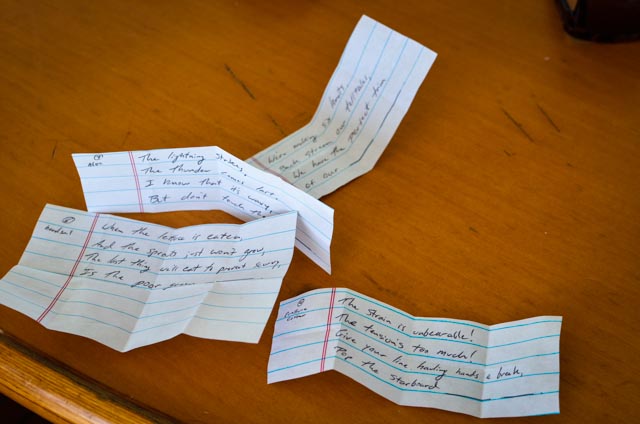

Oh yeah… and then I turned 32. That was a beautiful break from boat work, and we had a blast! For my birthday, Pete took me around the city to actually enjoy the sights of Miami. We walked around downtown, along the port, did some birthday present shopping, had mojitos and then a delicious seafood dinner. All of this was fabulous, buy my favorite part of the day was a little scavenger hunt that Pete organized for me on the boat. It was adorable and a fun adventure. I’m amazed at all the hiding places he found in our little 38’ by 20’ boat. I am most definitely a very lucky lady.

Mostly, we are simply waiting for the right weather window in order to cross the Gulf Stream and head to the Bahamas, but we are also using the time to get our boat in perfect condition to head offshore extensively. If we have the time, we figure we should use it to better our boat, as much as our skills and budget will allow. We are crossing our fingers to be heading to the Bahamas within a week. Cross yours for us while you’re at it. Can’t hurt, right?

Hi youse two!

Always enjoy receiving your updates…keeps me daydreaming here in the working world (not to mention chuckling with your good humor). Your slow but steady improvements towards the reliable function of your craft reminds me of our work on the used truck camper (aka June Buggy) prior to our North American tour de force before Chile…on a simpler and less costly plane, of course 🙂 My bugaboo was a smoking AC generator…ultimately fixing and indeed improving mechanical things is a mighty satisfying feeling indeed. Deeply rewarding to know how things work as well as the reward they give when carefully maintained…you will be happy for your hard-earned knowledge and maintenance when far offshore and in exotic but poorly stocked corners of the world. As such, take your time and do it right, as you apparently are. Safe passage to the Bahamas and a very happy birthday Miranda…our thoughts and prayers remain with you both, rain or shine, breeze or no…may your plugs continue to glow both onboard and inboard! Paul y familia